The promise of overseas manufacturing is compelling: high-quality, custom-made products at a fraction of the domestic cost. It’s how countless brands, artists, and organizations bring their visions to life. But this path is also filled with potential pitfalls. A simple oversight can lead to a disastrous order: pins that are poor quality, delivered late, or look nothing like your design. The financial loss is frustrating, but the damage to your brand’s reputation can be even worse.

This is your definitive guide to navigating that choice with confidence. We are pulling back the factory curtain to reveal the seven most critical—and completely avoidable—mistakes buyers make when ordering pins from overseas. By understanding these pitfalls and implementing our expert solutions, you can harness the incredible value of global manufacturing while confidently protecting your investment, your brand, and your peace of mind. For a complete overview of the entire creation process, you can always refer to our Ultimate Guide fir Benotzerdefinéiert Lapel Pins.

Inhaltsverzeechnes

Why This Guide is Essential for Your Business

For any B2B buyer, procurement manager, or marketing director, an overseas order is a calculated investment. This guide is designed to be your risk-management playbook. It will turn you from a first-time buyer into an informed, strategic partner in the manufacturing process, ensuring you can meet your budget, guarantee quality, and achieve your project goals without any costly surprises.

Mistake #1: Submitting Incorrect or “Broken” Artwork

The Problem: The “Garbage In, Garbage Out” Principle

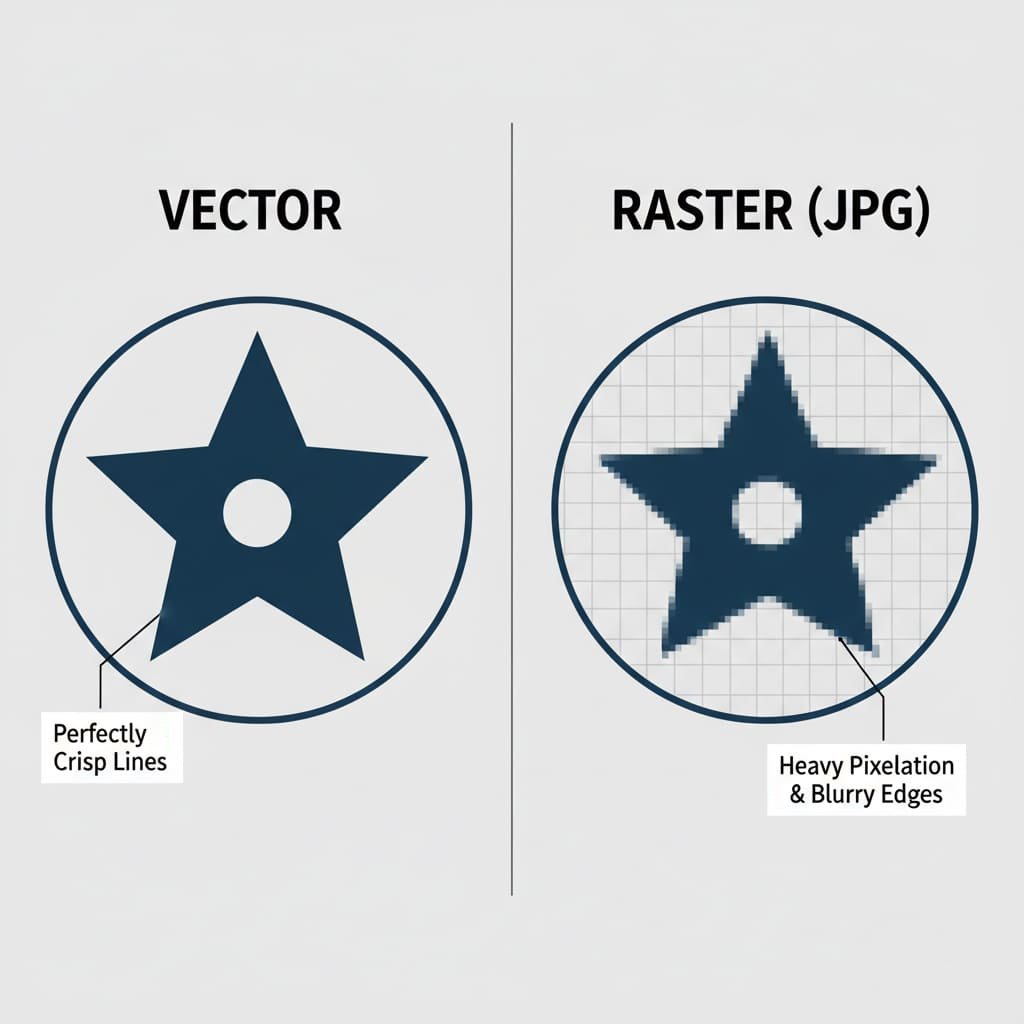

The single most common issue we encounter is receiving artwork that is not suitable for manufacturing. This can be a low-resolution JPG saved from a website, a blurry screenshot, or a digital painting with complex gradients. While these images might look fine on a screen, they are not a viable blueprint for creating a physical metal object.

Why It’s a Disaster for Your Project

- Production Delays: The entire process comes to a halt. The factory has to stop, contact you to explain the problem, and wait for a new, usable file. This can easily add days or even weeks to your timeline.

- Poor Quality Molds: If a manufacturer attempts to “make it work” with a bad file, the resulting steel mold will be flawed. It will have soft, blurry edges and lost details, a permanent flaw that will be transferred to every pin.

- An Unprofessional Final Product: The finished pins will lack the sharp, crisp metal lines that signify a high-quality product. This reflects poorly on your brand and can make your merchandise look amateurish and cheap.

The Proactive Solution: A Masterclass in Factory-Ready Files

The solution is to provide a **vector file**. This is the non-negotiable professional standard. A vector file is like a blueprint, made of mathematical lines and curves, which a machine can read to create a perfect mold. For a complete, non-designer-friendly masterclass on this crucial topic, you must read our Simple Guide to Vector Artwork for Pins.

File Type Showdown: Why Vector Wins

Vector vs. Raster for Pin Manufacturing

| Attribute | Vector (.AI, .EPS, .SVG) | Raster (.JPG, .PNG) |

|---|---|---|

| Scalability | Perfect quality at any size. | Becomes blurry and pixelated when enlarged. |

| Editability | Easily edit individual shapes and lines. | Difficult to edit without degrading quality. |

| Use for Molds | Ideal. Provides clean, precise paths for engraving. | Unusable. Creates messy, inaccurate molds. |

The artwork file is the single most important document in the entire process. It is the literal blueprint for the physical mold. Any error in the file will be permanently engraved in steel and reproduced on every single pin.

Mistake #2: Vague or Inaccurate Color Specifications

The Problem: “Just Use the Blue From My Website”

This is a dangerously common assumption. A buyer sends a file and assumes the factory can perfectly replicate the colors they see on their computer screen. As we’ve discussed, screen colors (RGB) are made of light and vary wildly between devices. They are not a reliable standard for physical products.

Why It’s a Disaster for Your Brand

- Brand Inconsistency: The final pin color will almost certainly not match your official brand color. This weakens your brand identity and can make your merchandise look like a cheap knock-off.

- Costly Remakes: If the color is wrong, the entire batch may need to be remade from scratch, potentially doubling your cost and your timeline.

The Proactive Solution: Speaking the Universal Language of Color

The only way to guarantee color accuracy is to use the Pantone Matching System (PMS). This is the universal language of color for manufacturing worldwide. By providing a specific Pantone Solid Coated (C) code, you are giving the factory an exact formula for the enamel paint. To learn how to find and use these codes, our in-depth article, Why Pantone Matching is Non-Negotiable, is an essential read.

Mistake #3: Choosing a Supplier Based on Price Alone

The Problem: Falling for the “Too Good to Be True” Quote

When searching on large marketplaces like Alibaba, you will find a vast range of prices. It is incredibly tempting to simply choose the supplier offering the absolute lowest price per pin. This is often a critical, and costly, mistake.

Why It’s a Disaster for Your Investment

- The “Bait and Switch”: That rock-bottom price is often for a product of vastly inferior quality. These suppliers may use cheap, thin base metals, poor quality enamel that chips easily, and have little to no quality control.

- Scams and “Ghosting”: In the worst-case scenario, the incredibly low price is from a fraudulent seller who will take your deposit and disappear, leaving you with no product and no recourse.

- No Support: When problems inevitably arise with a “too cheap” order, you will find that the customer service is non-existent.

The Proactive Solution: A Mini-Guide to Vetting Your Manufacturer

Choosing your manufacturing partner is the most important decision you will make. You are not just buying a product; you are hiring a team to execute your vision. For a full vetting checklist, you must read our complete Guide to Choosing a Reliable Custom Pin Manufacturer.

Quick Vetting Scorecard

Use this mental checklist when evaluating a potential supplier’s website.

| Criteria | Good Sign (Green Flag) | Warning Sign (Red Flag) |

|---|---|---|

| Website Professionalism | Clean, professional, detailed website. | Poorly designed, spelling errors, broken links. |

| Portfolio Quality | Shows many real, high-quality client projects. | Uses generic stock photos, few real examples. |

| Response Time | Responds to your quote in a few hours. | Takes days to respond to a simple inquiry. |

| Transparency | Clear pricing, upfront about the process. | Vague answers, avoids direct questions. |

Mistake #4: Rushing or Misunderstanding the Proofing Process

The Problem: Treating the Digital Proof as a “Rough Draft”

A digital proof (or mockup) is a technical blueprint that the manufacturer sends you for approval before starting production. A common mistake is to give it a quick glance, think “looks good enough,” and send back your approval without carefully checking every single detail.

Why It’s a Disaster for Accuracy

The proof is a binding contract. The factory is obligated to produce an exact replica of what is on that approved proof. If there is a spelling mistake, a wrong date, or an incorrect color code on the proof you approved, that mistake will be on every single one of your finished pins, and the fault will be yours.

The Proactive Solution: How to Review a Digital Proof Like an Expert

The proofing stage is your final, free chance to make changes. Treat it with the importance it deserves. Use this checklist to review your proof:

- Triple-Check All Spelling and Dates. Read every word carefully.

- Verify All Pantone (PMS) Color Codes. Ensure they match your brand guide.

- Confirm the Size/Dimensions. Check that the measurements are correct.

- Check the Plating Finish Specification. Is it “Polished Gold” or “Antique Gold”?

- Confirm the Backing Type and Post Count. Is it a rubber clutch? Is it the locking clutch you paid extra for? Does your large pin have two posts?

- Review the Backstamp Design. Is your logo or text on the back correct?

Mistake #5: Not Accounting for Hidden Costs

The Problem: An Incomplete or Deceptive Quote

You receive a quote that seems incredibly low, but it only lists a simple per-pin price. You place your order, only to be hit with a series of surprise charges later on.

Why It’s a Disaster for Your Budget

- Surprise Fees: The final invoice is suddenly inflated with unexpected charges for molds, setup, shipping, or customs after you’ve already committed.

- Add-On Markups: The cost balloons as you add features like glitter or special backings that you assumed were included or would be a minor upcharge.

The Proactive Solution: Demanding an All-Inclusive Quote

A professional manufacturer provides transparent, all-inclusive pricing. Before you commit, you should ask one simple question: “Is this the final, total price to my door?” A transparent quote will clearly itemize the per-pin cost, the one-time mold fee (and if it’s being waived), and all shipping, duties, and taxes. For a complete analysis of all potential costs, please see our Komplett Ënnerdeelung vun Benotzerdefinéiert Pin Präispolitik.

Mistake #6: Skipping the Sampling Step

The Problem: Trusting Website Photos Over Physical Reality

You choose a manufacturer based on the beautiful, glossy, professional photos in their online gallery. You assume your final product will look just like them.

Why It’s a Disaster for Quality Control

This is the classic “bait and switch.” The final pins arrive and they feel flimsy, the metal plating is thin and uneven, and the enamel fill is messy. You have no recourse because you approved the digital proof. The physical quality is something a digital image can never fully convey.

The Proactive Solution: Always See Before You Commit

The single best way to verify a manufacturer’s true quality is to get your hands on their product. Request physical samples. If they are confident in their work, they will be happy to send them. If physical samples aren’t possible due to time constraints, ask for photos of recent, real production runs, not just their curated portfolio shots. This is especially important for evaluating the tangible difference between pin types, as we show in our Hard vs Soft Email Verglach.

Mistake #7: Having an Unrealistic Timeline

The Problem: “I Need 1,000 Custom Pins for My Event in Two Weeks”

This is one of the most common and heartbreaking mistakes. A client drastically underestimates the time required for a multi-step, international manufacturing process that involves creating custom tooling from scratch.

Why It’s a Disaster for Your Event

- Your Pins Arrive Late: This is the most likely outcome, leaving you empty-handed for your crucial event.

- You Pay Huge Rush Fees: Expediting production and shipping is sometimes possible, but it always comes at a significant premium.

- Quality is Sacrificed: Rushing a handmade process often leads to a higher rate of defects and less stringent quality control.

The Proactive Solution: A Realistic Production and Shipping Calendar

Use this professional timeline to plan your project:

The Golden Rule: To be safe, you should plan for your pins to be in your hands at least 4-5 weeks from the day you approve your final artwork. For important, can’t-miss events, planning 6-8 weeks ahead is the professional standard.

Standard Custom Pin Production Timeline

| Stage | Estimated Time |

|---|---|

| Design & Proofing | 2-4 business days (depending on revisions) |

| Mold Creation & Mass Production | 2-3 weeks (10-15 business days) |

| International Air Shipping & Customs | 5-7 business days |

| TOTAL ESTIMATED TIME | Approx. 4-5 Weeks |

Bonus Mistake to Avoid: Forgetting the Back of the Pin

While 100% of the focus is usually on the front design, the back of the pin offers crucial opportunities for both function and branding.

- Use Two Posts on Large Pins: This prevents the pin from spinning and adds security.

- Add a Custom Backstamp: A professional touch that adds your logo or website to the back, reinforcing your brand and adding perceived value.

- Choose the Right Backing: A cheap clutch on a heavy pin is a recipe for disaster. For a full breakdown, see Den Ultimate Guide fir Pin Backings & Attachments.

Your Final Pre-Flight Checklist

Before you approve your order, run through this final checklist based on the solutions we’ve discussed.

- ☐ My artwork is in a proper vector format.

- ☐ I have specified exact Pantone (PMS) colors.

- ☐ I have thoroughly vetted my manufacturer beyond just their price.

- ☐ I will meticulously review every detail of the digital proof.

- ☐ I have received a clear, all-inclusive quote.

- ☐ I have seen physical samples or recent production photos.

- ☐ My timeline is realistic (at least 4-5 weeks).

Conclusion: Your Expert Partner in a Global Marketplace

Ordering custom pins from overseas offers incredible value, but it is not a commodity purchase. It is a partnership. Success requires a clear understanding of the process and a reliable, communicative partner who is committed to quality. The difference between a smooth, successful project and a frustrating failure often comes down to the manufacturer you choose to work with.

By avoiding these seven critical mistakes, you are no longer just a buyer; you are an informed project manager. You are equipped to protect your investment, ensure a high-quality product, and build a successful partnership that can bring your brand’s vision to life, time and time again. The final step is presenting your beautiful new pins professionally, a topic we cover in our Buyer's Guide to Custom Pin Packaging.

Let Us Be Your Expert Partner and Guide

Navigating the world of overseas manufacturing can be complex, but you don’t have to do it alone. We built our entire process to prevent these very mistakes. Our expert design team will ensure your artwork is perfect, our quotes are always transparent and all-inclusive, and our communication is second to none. Let us show you how easy and secure the process can be.