Wëllkomm! Dir hutt eng genial Iddi fir e personaliséierte Lapel Pin. Vläicht ass et fir Är Mark, e speziellen Event oder Äert wuessend Team. Mee wou fänks du un? D'Welt vun der Pin-Fabrikatioun ka komplex schéngen, voll mat technesche Begrëffer a kriteschen Entscheedungen. E klenge Feeler kann zu enger Partie Pins féieren, déi net richteg ausgesinn. Et ass e frustréierende Gedanken.

Hei trëppele mir an.Als Fabréck mat iwwer 250 qualifizéierten Mataarbechter hu mir alles gesinn. Mir hunn Dausende vu Clienten gehollef, grad wéi Dir, hir Visioun zu engem konkreten, héichqualitativen Produkt ze maachen. Dëse Guide ass eise Wee fir dës Erfahrung direkt mat Iech ze deelen. Mir wäerten Iech duerch all eenzel Schrëtt goen, déi komplex einfach maachen an Iech d'Vertraue ginn fir de perfekte Pin ze kreéieren. Fir Inspiratioun iwwer wéi Pins Är Mark erhéijen, entdeckt 15 Kreativ Weeër fir Benotzerdefinéiert Pins fir Äert Geschäft ze benotzen.

Inhaltsverzeechnes

Kapitel 1: D'Fondatioun: Versteesdemech Pin Typen

Ier Dir iwwerhaapt iwwer Design denkt, musst Dir de Stil vun Ärem Pin wielen. Dëse Choix beaflosst alles: d'Textur, d'Haltbarkeet, de Präis an d'Gesamtvibe. Loosst eis d'Haaptspiller opbriechen.Hard Email vs Soft Email: Déi grouss Debatt

Dëst ass déi allgemeng Entscheedung déi Dir maacht. Och wann hir Nimm ähnlech kléngen, sinn d'Endprodukter bemierkenswäert anescht. Denkt drun wéi Dir tëscht enger glänzender Foto an enger texturéierter Molerei wielt."Déi éischt Fro, déi mir ëmmer e Client stellen, ass iwwer déi virgesinn Notzung vum Pin. Ass et e Firmegeschenk fir Joeren ze daueren, oder e lëschtegen, trendy Artikel fir e Museksfestival? D'Äntwert weist bal ëmmer direkt op entweder haart oder mëll Email."

Hard Email vs Soft Email: Quick Verglach

| Fonktioun | Hard Emaille (Cloisonné) | Soft Email |

|---|---|---|

| Uewerfläch Gefill | Perfekt glat a flaach | Texturéiert, mat opgehuewe Metalllinnen |

| Haltbarkeet | Extrem héich, kraazbeständeg | Gutt, kann mat Epoxy verbessert ginn |

| Erkannt Wäert | Héich, Bijou-ähnlech | Exzellent, populär fir Retail / Konscht |

| Beschte Fir | Corporate Branding, Auszeechnunge a Luxusgidder | Promotiounen, Kënschtler Merch, Trading Pins |

| Käschten | Méi héich | Méi rentabel |

Aner Schlëssel Pin Stiler & Uwendungen

Nieft Email, e puer aner Stiler déngen spezifesch Besoinen:- Die Struck Pins: Denkt reng, klassesch Metal. Dës Pins hu keng Faarffill. Den Design gëtt mat opgehuewe an ageschniddene Metallberäicher erstallt. Si si perfekt fir en zäitlosen, elegante Look. Léiert méi an eisem Guide fir Classic, No-Color Metal Pins ze kreéieren.

- Gedréckte Pins (Offset): Wat wann Ären Design Gradienten, Schatten oder souguer eng Foto huet? Dat ass wou gedréckte Pins erakommen, wat fir onlimitéiert Faarf a fotorealistesch Detailer erlaabt. Entdeckt wéini gedréckte Pins fir komplex Designs ze wielen.

Kapitel 2: Design fir Fabrikatioun (DFM): De Blueprint fir Erfolleg

Dëst ass wou sou vill Projete falsch goen. En Design deen erstaunlech op Ärem Computerbildschierm ausgesäit kann onméiglech sinn als 1,25 Zoll Pin ze produzéieren. Fir Problemer ze vermeiden, ass et essentiell fir bescht Praktiken ze verfollegen. Eise Guide op der 10 Critical Design Tipps fir eng onvergiesslech Lapel Pin ze kreéieren ass e Must-Lies fir all Creator.

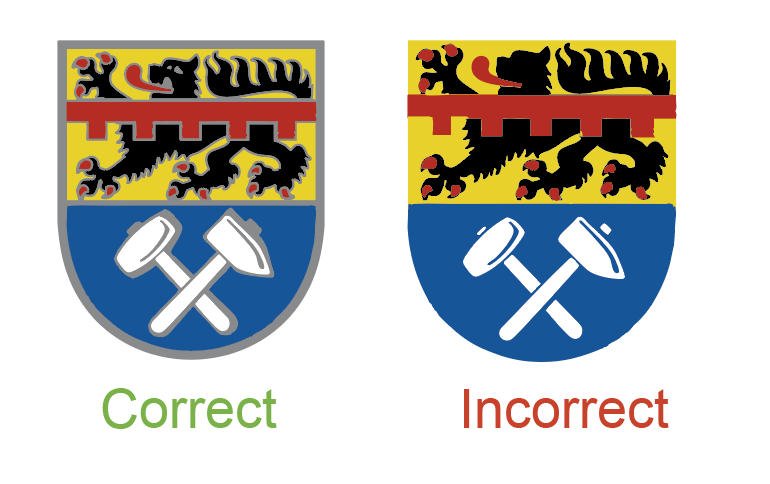

Regel #1: All Faarf brauch en Heem (getrennt vum Metal)

An engem Emaille Pin ass all Faarfberäich wéi eng kleng Schwämm. Déi opgehuewe Metalllinnen sinn d'Maueren vum Pool, déi de flëssege Email op der Plaz halen. Dofir muss all eenzel Faarf an Ärem Design komplett vun enger Metalllinn zougemaach ginn. Faarwe kënnen sech net direkt beréieren. Dëst ass déi wichtegst Regel am Pin Design.

Regel #2: Respektéiert d'Minimums

Eis Maschinnen an Handwierker sinn onheemlech präzis, awer si schaffen nach ëmmer an der kierperlecher Welt. Ze dënn Linnen oder Faarfberäicher déi ze kleng sinn, kënnen einfach net zouverlässeg produzéiert ginn.

Schlëssel Design Constraints fir Fabrikatioun

| Design Element | Minimum Gréisst / Dicke | Firwat Et Matters |

|---|---|---|

| Metal Linn Dicke | 0.2mm | Assuréiert datt d'Linn staark genuch ass fir Email ze halen an net beim Stamping ze briechen. |

| Faarf Beräich (Emaill Fëllung) | 0.3 mm | Garantéiert datt d'Email an d'Géigend fléien an se komplett ausfëllen. |

| Ausschnëtter (Bannen Lächer) | 1,5 mm - 2,5 mm | Verhënnert datt de Pin ënner dem Drock vun der Stampingpress kräizt oder briechen. |

| Textgréisst (Sans-Serif) | 6 pkt | Assuréiert datt d'Bréiwer liesbar sinn an d'Plazen an hinnen richteg ausgefëllt kënne ginn. |

Regel #3: D'Kraaft vu Pantone (PMS)

Fir Är Mark spezifesch Schatt vu blo ze garantéieren ass genee richteg, der Fabrikatioun Welt hänkt op der Pantone Matching System (PMS). Et ass wéi en universellt Rezeptbuch fir Faarf. Fir ze verstoen firwat dëst sou kritesch ass, kuckt eis Erklärer: Firwat Pantone ass net Verhandlunge fir Är Mark.

Regel # 4: Vecteure Fichieren sinn Kinnek

Gitt w.e.g. Är Konschtwierker als vektor Datei (.AI, .EPS, oder .SVG). Eng Pixel-baséiert Datei wéi e .JPG oder .PNG ass net ideal a muss nei gezeechent ginn. Fir eng kloer Erklärung, kuckt eis Einfach Guide fir Vector Artwork fir Net-Designer. Fir e méi techneschen Iwwerbléck, dëst Raster vs Vector Erklärer vun Adobe ass eng exzellent Ressource.

Kapitel 3: Material: De Kär vun Qualitéit

D'Basismetall vun Ärem Pin beaflosst säi Gewiicht, de erkannte Wäert an d'Eegeschaft fir verschidden Designen.

- Eisen: D'Workhorse, staark, zouverlässeg, a Käschten-effikass, mécht et déi gemeinsam Wiel fir mëll Emailen Pins.

- Messing: E Schrëtt erop, e bësse méi schwéier a méi mëll, wat e méi proppere Stempel erlaabt. Et ass dacks dat bevorzugt Material fir Premium hart Emaille Pins.

- Zink Legierung: De Spezialist. Am Géigesaz zu Eisen a Messing, déi gestempelt sinn, gëtt Zinklegierung aus engem geschmollte Staat gegoss. Dëst mécht et déi eenzeg Wiel fir Pins mat komplexen 3D Formen, scharfen internen Ecker oder grouss Ausschnëtter. Sidd Dir net sécher wéi eng Schimmeltyp Dir braucht? Liest eise Guide op 3D vs 2D Schimmel fir Benotzerdefinéiert Pins.

Kapitel 4: Plating: D'Finishing Touch

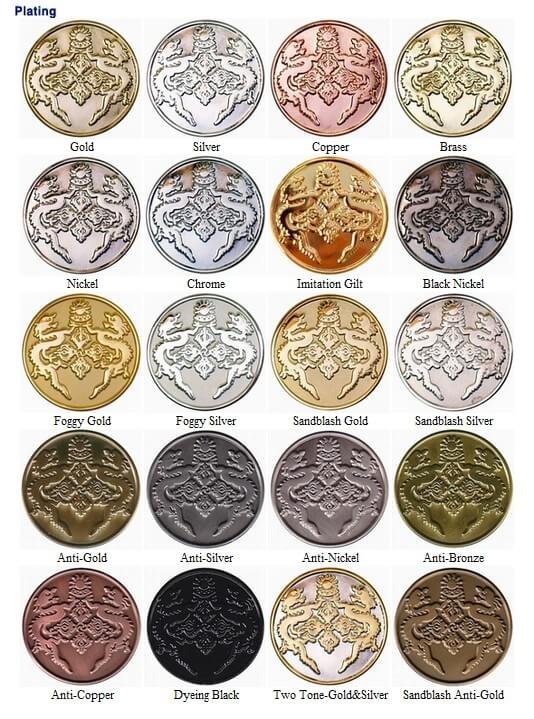

Plating ass déi dënn Schicht vu metallesche Finish, déi op Äre Pin applizéiert gëtt. Et ass wat d'Metalllinnen hir lescht Faarf a Glanz gëtt. Dëse Choix beaflosst dramatesch d'Stëmmung vun Ärem Pin.

"Eng einfach Ännerung am Plating kann en Design vu spilleresch bis prestigiéist huelen. Glänzend Gold fir en antike Sëlwerfinish austauschen kann e Pin fillen wéi en historeschen Artefakt. Et ass e mächtegt Tool."

Populär Metal Plating Optiounen

| Plating Typ | Beschreiwung | Beschte Fir |

|---|---|---|

| Glänzend Gold / Sëlwer | Héich poléiert, spigelähnlech Finish. Klassesch an hell. | Firmenlogoen, Auszeechnunge, Designen déi musse Pop. |

| Antik Gold / Sëlwer / Bronze | Chemesch al fir däischter ageschniddene Beräicher ze kreéieren, Detailer ënnersträichen. | Designs mat vill Textur, Vintage Looks, Militär oder Gedenkpins. |

| Black Nickel | Eng glat, donkel, bal gunmetal Finish. Modern a stilvoll. | Kontrastéiert mat helle Faarwen, schaaft en edgy oder zäitgenëssesch Gefill. |

| Rainbow / Anodiséiert | Eng iriséierend, multi-faarweg Finish wou d'Faarwen mam Liicht verschwannen. | Opfälleg an eenzegaarteg artistesch Pins. (Notiz: Nëmme verfügbar fir mëll Email). |

| Schwaarz gefierft | E matte, net reflektéierende schwaarze Finish. | E staarke Kontrast erstellen, dacks a Kënschtlerpins benotzt fir e fett Kontur. |

Déi richteg Plating ze wielen ass eng Konscht. Gesinn se all an eisem Visuell Guide fir Metal Plating Optiounen.

Kapitel 5: Backings & Uschlëss: The Unsung Hero

Wéi wäert Äre Pin un eng Jackett, Täsch oder Board befestigen? De Backing kann wéi e klengen Detail schéngen, awer et ass entscheedend fir Funktioun a Sécherheet. Fir e kompletten Iwwerbléck iwwer all verfügbare Optiounen, konsultéiert Den Ultimate Guide fir Pin Backings & Uschlëss.

Gemeinsam Pin Backing Optiounen

| Backing Typ | Beschreiwung | Benotzt Case |

|---|---|---|

| Päiperlek Kupplung | D'Industrie Norm. Eng Metallkupplung déi Dir dréckt fir ze befreien. | Standard fir déi meescht Pins. Gutt fir allgemeng Benotzung. |

| Gummi Kupplung | Eng mëll PVC Kupplung. Méi bequem géint Haut a ganz sécher. | Wearable Artikelen, Kënschtler Pins, e populäre a bezuelbare Upgrade. |

| Deluxe / Sperrkupplung | E Fréijoersbelaaschte Mechanismus deen op d'Poste gespaart ass. Ganz sécher. | Verhënnert Verloscht vu wäertvollen oder sentimentale Pins. Great fir Händler. |

| Sécherheet Pin | Eng traditionell Brosche-Stil Pin zréck. | Méi grouss Pins oder fir Stoffer ze befestigen wou e Post net funktionnéiert. |

| Magnete | Zwee mächteg Magnete (een op der Pin, een fir bannen an der Kleeder). | Delikat Stoffer wéi Seid oder fir jiddereen deen net e Pinhole wëll. |

Pro Tipp: Fir Pins méi grouss wéi 1,25 Zoll, benotzt ëmmer zwee Posts op der Réck. Dëst verhënnert datt de Pin dréint an hält se sécher op der Plaz.

Kapitel 6: Bannen an der Fabréck: Wéi Äre Pin ass gebuer

Hutt Dir jeemools gefrot wat geschitt nodeems Dir Ären Design guttgeheescht hutt? Et ass eng faszinéierend Mëschung vu schwéiere Maschinnen a qualifizéierten Handwierk. Hei ass déi vereinfacht Rees vun enger digitaler Datei op e fäerdegt Produkt.

Schimmel Schafung: Är Vektorgrafik guidéiert eng CNC Maschinn fir Ären Design, ëmgedréint, an e festen Stahlblock ze gravéieren. Dëse Schimmel ass d'Häerz vum Produktiounsprozess.

Stempel: Eng massiv hydraulesch Press, déi e puer Tonnen Drock applizéiert, schloen Sträifen vun Ärem gewielte Basismetall (Eisen oder Messing) géint d'Schimmel. Dëst erstellt déi flaach Pin "Blanks" mat Ärem Design beandrockt an hinnen.

Trimmen: Déi eenzel Pin Formen ginn aus de Metallstreifen ausgeschnidden.

Poléieren: Déi rau Metal Pins ginn getrommelt a poléiert fir all rau Kante vum Stampingprozess ze glatten.

Befestigung Schweess: D'Backingposte ginn suergfälteg op de Réck vun all Pin geschweest.

Plating: D'Pins ginn an engem chemesche Bad elektroplatéiert fir hinnen hir lescht Metallfinish ze ginn (zB Gold, schwaarze Néckel).

Emaille Füllung: Dëst ass wou d'Kënschtlerin blénkt. Kompetent Aarbechter benotzen kleng Sprëtzen fir suergfälteg all ageschniddene Gebitt vum Pin mat flëssege Emailfaarf ze fëllen, eng Faarf gläichzäiteg.

Baken: D'Pins ginn an engem nidderegen Temperaturofen gebak fir d'Email ze heelen an ze härten.

Finale poléieren (nëmmen schwéier Email): Hard Emaille Pins ginn duerch en zousätzleche strenge Schleif- a Polierprozess fir d'Uewerfläch perfekt flaach a glat ze maachen.

Qualitéitskontroll: All eenzel Pin gëtt mat der Hand iwwerpréift. Mir kontrolléieren op Faarfgenauegkeet, Kratzer, Stëbs am Email, an all aner Mängel. Nëmmen déi bescht maachen et duerch.

Kapitel 7: Wiel vun der rietser Partner: Fabréck vs Middleman

Dir hutt Ären Design perfektionéiert. Elo braucht Dir een fir et ze maachen. Dëst ass eng kritesch Wiel. Eis detailléiert Guide erkläert wéi en zouverléissege personaliséierte Pin Hiersteller ze wielen a vermeiden potenziell Problemer.

"Déi gréissten Frustratioun fir Keefer kënnt aus Kommunikatioun Decompte. Wann et méi Schichten tëscht Iech an de Leit déi tatsächlech de Produit maachen, Detailer ginn verluer. Fabréck direkt schafft dës Reibung ewech. Dir schwätzt mat den Experten."

Hei ass wat Dir an engem Fabrikatiounspartner kuckt:

- Déif Erfahrung: Sinn se eng grouss Varietéit vu komplexe Pins? Eng erfuerene Fabréck huet Problemer geléist, op déi Dir nach net geduecht hutt. Gesinn e Beispill an eisem Fallstudie iwwer Mataarbechter Moral Pins.

- Transparent Kommunikatioun: Sinn se reaktiounsfäeger a bidden se Expert Berodung?

- Kloer Zitat: Den Zitat soll einfach an all-inklusiv sinn.

- Eng zolitt Garantie: Eng renomméiert Fabréck wäert op hir Aarbecht stoen.

Schafft direkt mat enger Fabréck gëtt Iech besser Präisser an eng méi héich Qualitéit Finale Produit. Fir Problemer ze vermeiden, gitt sécher iwwer ze liesen déi Top 7 Feeler fir ze vermeiden wann Dir personaliséiert Pins bestellt.

Kapitel 8: De Standard Procurement Workflow: Vun Zitat bis Liwwerung

Also, wéi gesäit de Bestellungsprozess eigentlech aus? Et ass en einfache Wee entworf fir sécherzestellen datt Dir genau kritt wat Dir wëllt, ouni Iwwerraschungen.

- Ufro fir Zitat (RFQ): Dëst ass den Ufank. Dir schéckt eis Är Konschtwierker (och eng rau Skizz ass an der Rei!), Déi gewënscht Gréisst, d'Quantitéit déi Dir braucht, an de Pin-Stil un deen Dir denkt.

- Formell Zitat & Digital Beweis: Bannent 24 Stonnen schéckt eis Team zwou Saachen zréck:

- En detailléierten, itemiséiert Devis mat all Käschten kloer ausgeluecht.

- E professionnelle digitale Konschtwierk Beweis. Dëst ass eisen technesche Blueprint fir Äre Pin. Et wäert déi lescht Zeilkonscht weisen, Pantone (PMS) Faarfcoden, Gréisst, Platingwahl a Backing-Typ.

- Revisiounen & Genehmegung: Dëst ass Är Chance fir Ännerungen ze maachen. Braucht Dir eng Faarf tweaked? Wëllt Dir den Text e bësse méi grouss maachen? Mir bidden onlimitéiert Versioune gratis. Mir wäerten net eng eenzeg PIN produzéiere bis Dir mat Ärer formell Genehmegung vun dësem Beweis geäntwert.

- Produktioun: Wann Dir de Beweis guttgeheescht hutt an d'Bezuelung ofginn, geet Är Bestellung op de Fabrécksbuedem. Dëst ass wou d'Magie geschitt! D'Produktioun dauert normalerweis 2-3 Wochen.

- Versand: Nodeems Dir eis lescht Qualitéitskontrollprüfung passéiert hutt, ginn Är Pins sécher verpackt an direkt op Är Dier iwwer en zouverléissege internationale Courrier wéi FedEx oder DHL geschéckt.

Kapitel 9: Oft gestallte Froen (FAQ)

Mir kréien dës Froen all Dag. Hei sinn déi kloer, einfach Äntwerten déi Dir braucht.

- 1. Wat ass Är Minimum Order Quantitéit (MOQ)?

- Eis Standard MOQ ass 100 Pins pro Design. Well de Setupprozess (Schimmelschafung, Maschinnkonfiguratioun) den Aarbechtsintensivsten Deel ass, gëtt méi kleng Quantitéite ganz deier pro Stéck. D'100-Eenheet Mark ass wou de Präis wirtschaftlech gëtt.

- 2. Wat ass eng "Schimmelgebühr"? Ass et wierklech eng eemoleg Charge?

- Jo, absolut. D'Schimmelgebühr deckt d'Käschte fir déi kierperlech Stahlschimmel fir Äre spezifesche Design ze kreéieren. Mir späicheren Är Schimmel sécher fir 2 Joer. Wann Dir eng nei Uerdnung vun der exakt selwechter PIN bannent där Zäit Plaz, Dir wäert net d'Schimmel dossier bezuelen erëm.

- 3. Wat ass déi duerchschnëttlech Gesamtzäit?

- Vum Moment wou Dir Äre Beweis guttgeheescht hutt, sollt Dir ongeféier 3-4 Wochen plangen. Dëst brécht op ongeféier 2-3 Woche fir d'Produktioun a 5-7 Deeg fir international Loftverschécken.

- 4. Ech hu kee berufflechen Design, just eng Iddi. Kënnt Dir hëllefen?

- Natierlech. Eist Team vu Kënschtler kann Är rau Skizz, Logo, oder souguer nëmmen eng detailléiert Beschreiwung an e Produktiounsfähig digitale Beweis ëmsetzen, komplett gratis.

- 5. Kann ech eng eenzeg kierperlech Prouf virum voll Laf bestellen?

- Jo, e Pre-Produktiounsprobe erstellen ass méiglech. Dëst ass eng super Optioun fir ganz grouss Bestellungen (5,000+ Unitéiten) oder fir Clienten déi de kierperleche Produkt fir endgülteg Genehmegung mussen hunn. Notéiert w.e.g. datt dëse Prozess eng Probegebühr involvéiert an ongeféier 2-3 Wochen un d'Gesamtzäitlinn bäidréit.

- 6. Wat geschitt wann ech e Feeler oder Defekt a menger Bestellung fannen?

- Är Bestellung ass garantéiert fir den digitale Beweis ze passen deen Dir guttgeheescht hutt. Wann Dir Är Pins kritt a si hunn e Fabrikatiounsdefekt oder passen net mam Beweis, wäerte mir déi defekt Pins fir Iech op eise Käschten nei maachen.

- 7. Wéi vill kascht e personaliséierte Pin?

- De Präis baséiert op der Gréisst, Quantitéit, Pin Stil, an Zuel vu Faarwen. Fir e kompletten Iwwerbléck, liesen weg Benotzerdefinéiert Pin Präispolitik verstoen: E komplette Decompte an Wéi Pin Gréisst a Komplexitéit Afloss op d'Finale Käschte.

- 8. Kënnt Dir Pins mat speziellen Features wéi Glitter oder Ausschnëtter maachen?

- Jo! Mir Léift speziell Funktiounen. Entdeckt d'Méiglechkeeten an eisem Guide fir Spezialeffekter fir Pins (Glitter, Glow-in-the-Dark, a Méi).

- 9. Wat sinn Är Bezuelungsbedéngungen?

- Fir nei Clienten erfuerdere mir voll Bezuelung nodeems d'Konschtbeweis guttgeheescht ass awer ier mir d'Massproduktioun ufänken. Mir akzeptéieren all gréisser Kreditkaarten an Iwwerweisungen.

- 10. Bitt Dir personaliséiert Verpackungen?

- Mir maachen. Iwwerdeems all PIN kënnt an seng eege individuell Poly Sak fir Schutz, mir kënnen och Mooss Optiounen schafen. Gesinn all Optiounen an A Buyer's Guide to Custom Pin Packaging.