Designing a custom enamel pin is an exciting creative process. It’s an opportunity to turn an idea—a brand logo, a piece of art, a memorable slogan—into a tangible, wearable object. But it’s also a process full of unique technical challenges. An image that looks stunning on a computer screen can quickly become a blurry, unreadable mess if not designed with the physical manufacturing process in mind.

This is where so many projects encounter frustration. The good news? It’s completely avoidable. With a bit of expert knowledge, you can create a design that is not only beautiful but also perfectly optimized for production. As a leading pin manufacturer, we’ve guided thousands of clients, from professional graphic designers to first-time creators, through this very process. We’ve seen what works, what doesn’t, and why.

This definitive guide is our way of sharing that expertise with you. We will walk you through the ten most critical design rules that will ensure your final product is something you can be proud of. Whether you’re a seasoned artist or sketching on a napkin, these tips will give you the confidence to create an unforgettable lapel pin. For a complete overview of the entire creation process from start to finish, you can always refer back to our Ultimate Guide fir Benotzerdefinéiert Lapel Pins.

Inhaltsverzeechnes

Tip 1: Start with a Clear Concept and Purpose

Before you draw a single line, the most important step is to define the “why” behind your pin. A great pin isn’t just a random collection of cool elements; it’s a focused message delivered in a tiny package. A clear purpose will guide every single design decision you make, from color choice to the final shape.

What is the pin’s primary job?

Ask yourself what you want this pin to achieve. Its function will dramatically influence its design.

- For Corporate Branding: The goal is instant recognition and professionalism. The design should be clean, centered around your logo, and use brand colors accurately. A sleek Hard Enamel finish is often preferred for its jewelry-like quality.

- For a Promotional Giveaway: The goal is to be eye-catching and memorable. This is where you can use brighter colors, fun shapes, and perhaps a clever slogan. Cost-effectiveness is key, making Soft Enamel a popular choice.

- For Employee Recognition: The goal is to convey value and honor. The design should feel prestigious, perhaps incorporating the company logo with text like “5 Years of Service.” Metallic finishes like polished or antique gold work well. See a great example in our case study on employee morale pins.

- For Retail or Artist Merchandise: The goal is creative expression and collectibility. This is where you have the most freedom. The design is the product, so uniqueness and high artistic quality are paramount.

Who is your target audience?

Designing for a corporate executive is very different from designing for a music festival attendee. Think about who will be receiving and wearing this pin. What styles resonate with them? A design for a youth sports team might be bold and playful, while a pin for a professional association should be more understated and elegant.

Tip 2: Embrace Simplicity and Boldness

This is perhaps the most repeated, and most important, piece of advice in pin design: less is more. Your canvas is tiny, often no larger than a quarter. Designs that are overly complex, crowded, or filled with tiny details will lose their impact and can become unreadable when produced at such a small scale.

Why does simplicity work so well for pins?

A pin is most often viewed from a distance, on a lapel, jacket, or backpack. A simple, bold design with clean lines and strong color contrast will be instantly recognizable and visually appealing. A cluttered design just looks like a confusing smudge from a few feet away. The goal is to create a design that is clear and intentional, ensuring your core message is not lost in the noise.

Tip 3: Master the Rules of Lines and Colors

This is the most technical—and most critical—part of pin design. Understanding how metal lines and enamel colors interact in the physical world is non-negotiable. It’s the difference between a professional proof and a design that gets rejected by the factory.

The #1 Rule: All Colors Must Be Separated by Metal Lines

Think of an enamel pin like a stained-glass window or a coloring book. The raised metal lines (called “die lines”) act as walls that contain the liquid enamel paint. Without these walls, the colors would bleed together during production. Therefore, every single area of color in your design must be fully enclosed by a metal outline. Colors cannot touch each other directly.

Understanding Minimum Thickness and Area

While our factory technology is incredibly precise, we are still working with physical materials. If lines are too thin or color areas are too small, they cannot be reliably manufactured.

Essential Manufacturing Specifications

| Design Element | Minimum Size / Thickness | Why It’s a Rule |

|---|---|---|

| Metal Line Thickness | 0.2mm (approx. 0.75pt stroke) | Ensures the metal wall is strong enough to not break during stamping and to properly contain the enamel. |

| Color Fill Area | 0.3mm wide | Guarantees that the liquid enamel can flow into the space completely and create a solid color area. |

Using Pantone (PMS) for Perfect Color Matching

The colors you see on your screen (RGB) are different from the colors in print (CMYK), and both are different from enamel paint. To ensure your brand’s specific shade of red is reproduced with perfect accuracy, the entire manufacturing industry uses the Pantone Matching System (PMS). This is a standardized color library where each color has a specific code. Providing the PMS codes for your design is the only way to guarantee precise color results. If you don’t know them, our team can help you find the closest match. For a deeper understanding, explore our guide on why Pantone matching is critical for your brand.

Can You Use Gradients or Shading?

No. The traditional enamel pin process only works with solid, flat colors. Gradients, shading, and photographic elements cannot be reproduced. If these are essential to your design, the solution is to opt for a Gedréckt Pin, which prints your design directly onto the metal base and seals it with an epoxy dome. Learn more in our guide on when to choose printed pins.

Tip 4: Make Your Text Clear and Legible

Including text on a pin can be incredibly effective, but it’s also one of the easiest things to get wrong. Illegible text is a wasted opportunity. Due to the small scale, typography requires careful planning.

How to Ensure Your Text is Readable

- Keep it Brief: You don’t have space for a paragraph. Stick to a few essential words—a brand name, a date, a short slogan. A good rule of thumb is to stay under 10-15 words total.

- Choose Simple, Bold Fonts: Clean, sans-serif fonts (like Arial, Helvetica) are almost always the best choice. Overly decorative, thin, or script fonts become impossible to read when shrunk down to pin size.

- Respect the Minimum Size: For text to be legible, it must adhere to minimum size constraints.

Typography Guidelines for Custom Pins

| Element | Minimum Requirement | Reason |

|---|---|---|

| Font Size | 5pt – 6pt | Ensures basic legibility for a standard sans-serif font. |

| Stroke Thickness (of letters) | 0.2mm | Guarantees the metal can form the letter shape correctly. |

| Enclosed Space (e.g., inside an ‘O’) | 0.3mm | Allows space for the enamel to be filled, if applicable. |

A Critical Technical Step: Convert Text to Outlines

In your digital design file, your text is likely an editable font. If our designers don’t have that exact font installed, their computer will substitute it, ruining your design. To prevent this, you must convert all text to outlines (or curves) before sending the file. This turns the letters into fixed vector shapes, ensuring they look exactly as you intended, no matter who opens the file.

Tip 5: Choose the Right Size and Shape for Your Purpose

The physical dimensions of your pin are a core part of its design and impact. This decision should be a balance between detail, wearability, and budget.

What is the most common pin size?

The vast majority of custom lapel pins fall between 1.0 inch and 1.5 inches. This size range offers a great balance: large enough to showcase a good amount of detail, but small and light enough to be comfortably worn on a jacket, lanyard, or backpack.

- Under 1.0 inch: Best for very simple logos or icons. Subtle and professional.

- 1.0″ – 1.5″: The versatile sweet spot for most designs.

- 1.75″ – 2.0″+: Considered large. Excellent for trading pins or detailed art pieces, but can be heavy.

The size of your pin also has a direct impact on the final cost. For a complete breakdown, consult our insider’s look at how pin size affects cost.

Pro Tip: A simple way to visualize the final size is to print your design on paper at its actual size and cut it out. This gives you a real-world sense of its scale and impact.

Thinking Outside the Box with Custom Shapes

Don’t feel constrained to circles and squares! One of the best things about custom pins is that they can be cut to almost any shape. A custom shape that follows the outline of your design is more dynamic, eye-catching, and feels more unique. This is included at no extra cost and is a fantastic way to make your pin stand out.

The shape of your pin is just as important as the design within it. A creative shape can turn a simple logo into a memorable keepsake. It’s an easy way to elevate your design without increasing the cost.

Tip 6: Use the Metal Plating as a Design Element

Many new designers think of the metal lines only as necessary borders. But expert designers know that the metal itself is a key color in your palette. The choice of metal plating can dramatically change the mood and impact of your artwork.

How to Choose a Complementary Plating

Think about contrast and harmony. Your enamel colors should work with, not against, your chosen metal finish.

- Polished Gold: Classic and prestigious. It makes dark colors like navy blue, deep red, and forest green “pop” with a rich contrast.

- Polished Silver/Nickel: Modern and versatile. It works well with most colors but can sometimes wash out very light colors like pale yellow or white.

- Black Nickel: Edgy and contemporary. It provides a fantastic contrast for very bright, vibrant, or neon colors.

- Antique Finishes (Gold/Silver/Bronze): These have a darker, recessed texture that is perfect for adding a vintage feel or highlighting fine details in die-struck (no color) pins.

Before you finalize your colors, place them next to your intended plating color in your design software. This simple check ca

Tip 7: Add Special Effects and Features Thoughtfully

If you want to take your design to the next level, a variety of special effects can be added. When used correctly, these can make your pin a true standout piece. However, use them thoughtfully to enhance your design, not overwhelm it.

Popular Special Features

- Glitter Enamel: Adds sparkle and visual interest to specific color areas. Perfect for magical or celebratory designs.

- Glow-in-the-Dark Enamel: A fun surprise that makes parts of your pin glow after being charged in light.

- Translucent Enamel: Creates a beautiful, stained-glass effect when applied over a textured metal area.

- Spinners, Sliders, Danglers: These add kinetic, interactive elements to your pin, making them highly collectible but also increasing the cost.

For a detailed look at these options and how they impact price, see our Guide to Special Effects for Pins.

Tip 8: Design for Structural Integrity (Cutouts)

Hollow areas, or “cutouts,” can add a lot of visual interest to a pin, creating negative space that makes the design feel lighter and more intricate. However, these holes must be designed with the physical strength of the metal in mind.

The Rules for Cutouts

If a cutout area is too small or too close to a delicate part of the pin, it can cause the metal to warp, bend, or break during the high-pressure stamping process.

Guidelines for Cutout Designs

| Pin Thickness | Minimum Inner Hole Size |

|---|---|

| 1.0mm – 2.0mm (Standard) | At least 1.5mm |

| 3.0mm (Extra Thick) | At least 2.5mm |

For more complex designs with multiple levels, you may need to consider a 3D mold. Learn more in our guide comparing 3D vs. 2D Molds for Custom Pins.

Tip 9: Prepare Your Artwork for the Factory

You’ve finalized your design. The last step is to prepare the digital file correctly. Providing a factory-ready file will speed up the process and minimize the risk of errors in translation.

Vector is Best: The Ideal File Formats

The gold standard for pin manufacturing is a vektor Datei. Unlike pixel-based images (like JPGs), vectors are made of mathematical lines and curves. This means they can be scaled to any size without losing a single bit of quality, which is essential for creating a perfect mold.

- Preferred Formats:

.AI(Adobe Illustrator),.EPS,.PDF(saved from vector software),.SVG. - Acceptable Formats: If you don’t have a vector file, a high-resolution raster file (

.JPG,.PNG,.PSD) at 300 DPI or higher will work. Our artists will then need to manually redraw it into a vector format for production. This is a crucial step, as explained in our Simple Guide to Vector Artwork for Non-Designers.

For an excellent external resource on this topic, see this Raster vs. Vector explainer from Adobe.

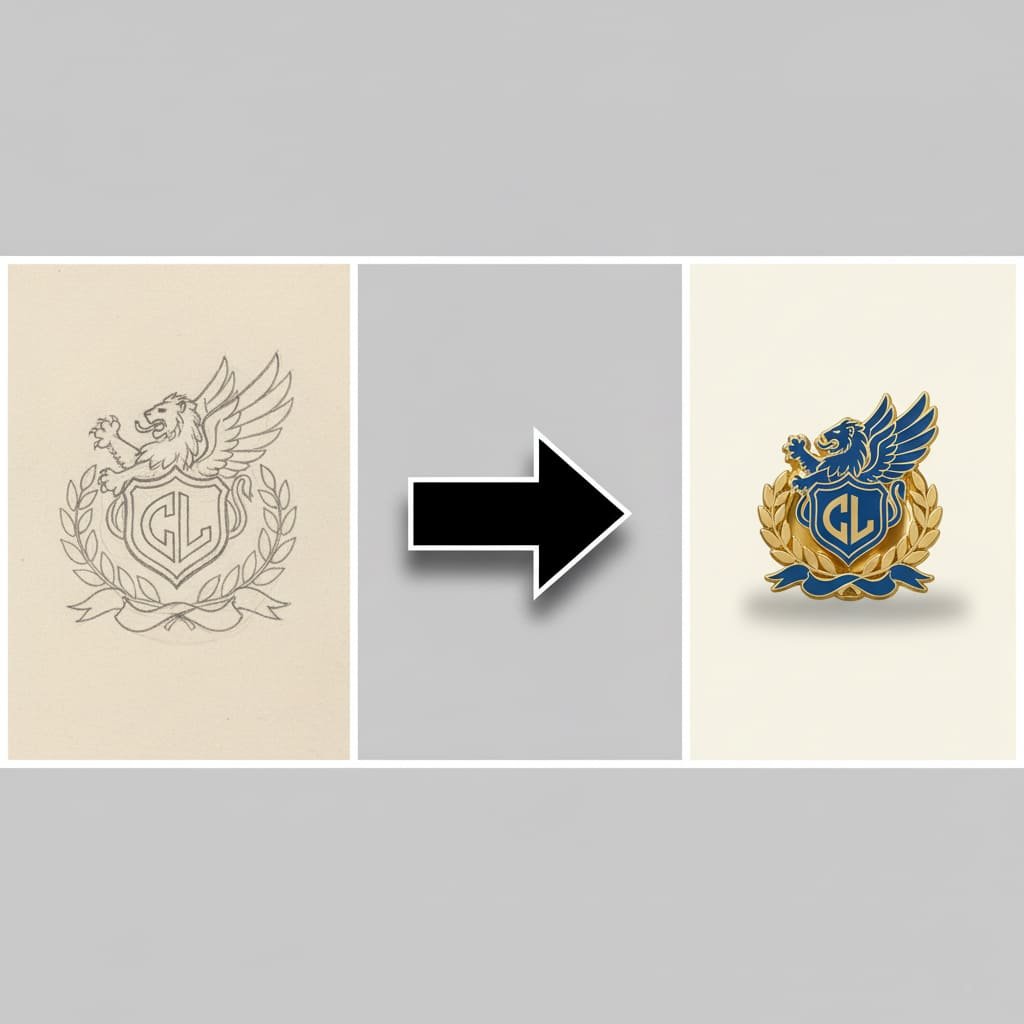

What if I only have a hand-drawn sketch?

That’s perfectly fine! A clear sketch on paper is all we need to get started. Just take a high-quality photo or scan of your drawing. Our professional design team will turn your sketch into a digital, production-ready proof for your approval, and this service is completely free.

Tip 10: Don’t Forget the Back of the Pin

While everyone focuses on the front, the back of the pin offers opportunities for both function and branding.

Choose the Right Number of Posts

A single post in the center is standard for most pins under 1.25 inches. However, for larger, longer, or irregularly shaped pins, it is highly recommended to use two pin posts. This provides two points of contact, preventing the pin from spinning around when worn and making it far more secure. You can explore all the options in Den Ultimate Guide fir Pin Backings & Attachments.

Add a Custom Backstamp for Branding

A backstamp is your logo, website URL, or brand name lightly imprinted into the back of the pin. It’s an incredibly professional touch that adds perceived value and reminds people where their awesome pin came from. It’s a subtle but powerful marketing tool that marks the pin as your own original creation.

Conclusion: You’re Ready to Design

Designing a custom enamel pin doesn’t have to be intimidating. By following these ten critical tips, you can bridge the gap between creative vision and manufacturing reality. From establishing a clear concept and embracing simplicity to mastering the technical rules of lines, colors, and file preparation, you now have the expert knowledge to create a design that is effective, beautiful, and ready for production. To avoid potential headaches, be sure to review our guide on the top 7 mistakes to avoid when ordering custom pins.

Remember that you’re not alone in this process. A great manufacturing partner will work with you, review your artwork, and provide professional feedback to ensure the best possible result. Now, go unleash your creativity and design an unforgettable pin!

Ready to Bring Your Design to Life?

You’ve got the knowledge, now it’s time to take the next step. Our team of expert designers is ready to take your idea—whether it’s a finished vector file or a simple sketch—and turn it into a free, professional digital proof for your review. There is no cost and no obligation.