Du har sendt inn to forskjellige pin-design for et tilbud. Den ene kommer tilbake på $2,50 per stykke, den andre på $5,50. De er like store, så hva gir? Verden av tilpasset produksjon er fylt med variabler som kan virke mystiske, men de er alle forankret i en enkel virkelighet: tid, materialer og arbeid. Å forstå disse faktorene er nøkkelen til å mestre budsjettet ditt og designe en pinne som er både fantastisk og kostnadseffektiv.

Dette er din definitive "insiders titt" på økonomien til pinneproduksjon. Vi vil trekke fabrikkgardinet tilbake og bryte ned, i uttømmende detalj, nøyaktig hvordan pinnestørrelse og designkompleksitet oversettes til virkelige kostnader. Ved slutten av denne veiledningen vil du ikke bare forstå pristilbudet ditt, men vil også være bemyndiget til å ta strategiske designvalg som gir deg den absolutt beste verdien for investeringen din. For en fullstendig oversikt over hele opprettelsesprosessen kan du alltid henvise til vår Ultimate guide til tilpassede jakkeslagsnåler.

Innholdsfortegnelse

Kjerneligningen for pinneproduksjon

I hjertet bestemmes prisen på en hvilken som helst egendefinert pin av en enkel ligning. Å forstå dette konseptet er det første trinnet for å forstå sitatet ditt.

Formelen er enkel: (Størrelse + kompleksitet) ÷ Antall = din endelige kostnad per pin. Mens denne veiledningen fokuserer på størrelse og kompleksitet, må du aldri glemme kraften i kvantitet. Det er den store multiplikatoren – eller deleren – av kostnadene dine.

De tre store kostnadsdrivertabellen

De viktigste faktorene som styrer prisen på pinne

| Primær kostnadsdriver | Hvorfor det betyr noe | Innvirkning på sluttpris |

|---|---|---|

| Mengde | Fordeler faste installasjonskostnader (som den tilpassede formen) over flere enheter, noe som gjør hver pinne billigere. | Eksponentiell. Den største enkeltfaktoren for å senke prisen per pinne. |

| Størrelse | Påvirker direkte mengden råmaterialer som brukes, pinnens vekt og maskintiden som kreves. | Lineær. En større pinne vil alltid koste mer enn en mindre. |

| Kompleksitet | Direkte påvirker mengden av dyktig arbeidstid, behovet for spesialiserte materialer og potensialet for defekter. | Variabel. Den mest nyanserte faktoren, med mange ulike kostnadsnivåer. |

En mesterklasse i størrelse: mer enn bare millimeter

Den fysiske størrelsen på pinnen din er en av de mest direkte og lettfattelige kostnadsdriverne. La oss bryte ned nøyaktig hvordan det påvirker den endelige prisen.

Råvareforbruk

Dette er den mest åpenbare faktoren. En 2-tommers pinne har fire ganger overflatearealet til en 1-tommers pinne med samme design. Dette betyr at det krever fire ganger så mye råmetall og fire ganger så mye emaljemaling å produsere. Denne direkte økningen i materialkostnader er en primær komponent i den høyere prisen.

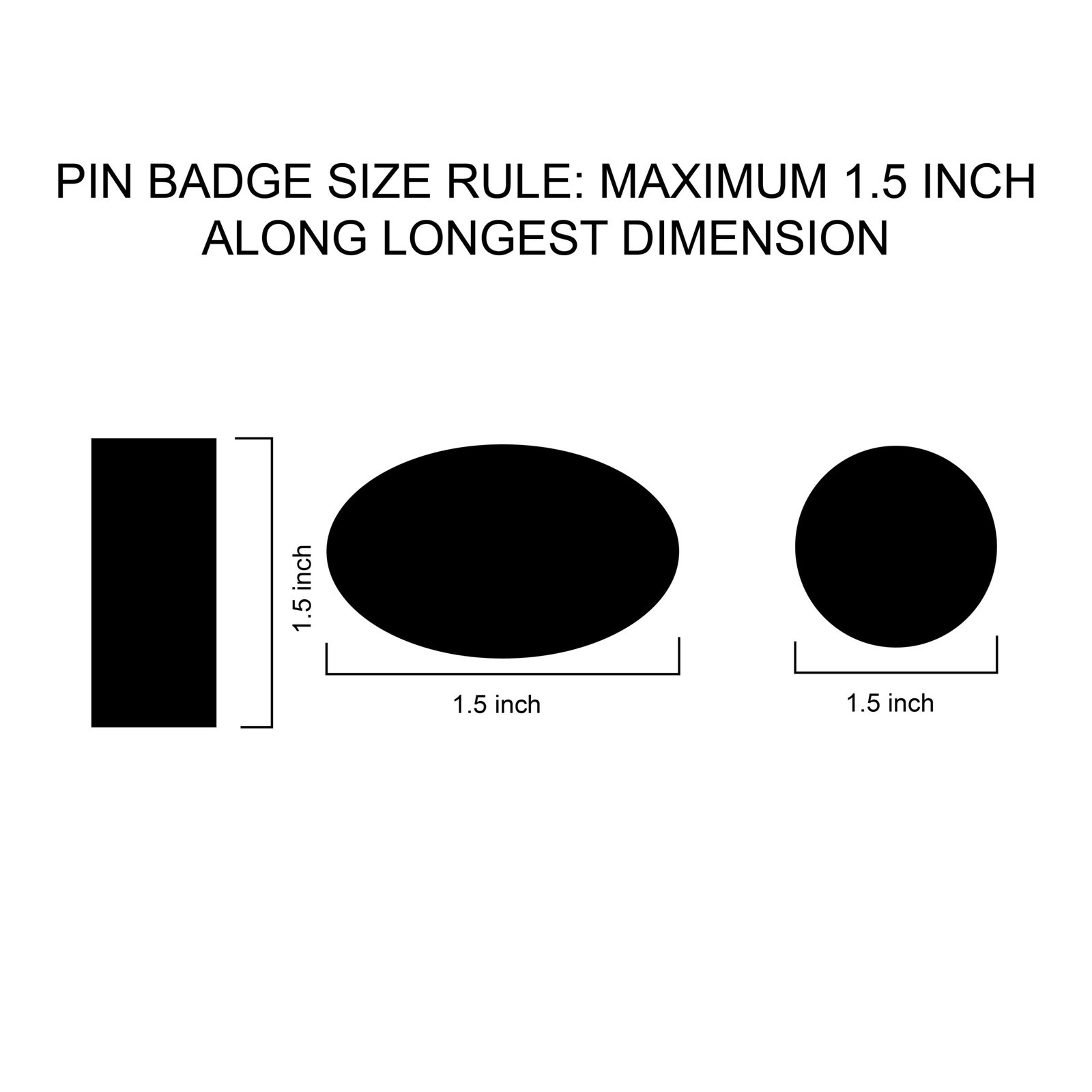

Hvordan nålstørrelse måles: «Lengste dimensjon»-regelen

Dette er et vanlig forvirringspunkt for nye kjøpere. En pins størrelse bestemmes av dens lengste punkt, enten det er høyden eller bredden. Så en rektangulær pinne som er 1,5 tommer høy og 1,0 tommer bred er priset som en 1,5 tommers pinne. En sirkulær pinne som er 1,25 tommer i diameter er priset som en 1,25 tommers pinne. Du trenger ikke fylle hele området; prisen er basert på lengst mulig måling.

Den skjulte faktoren: Hvordan størrelsen påvirker tykkelsen

For å opprettholde dens strukturelle integritet, må en større pinne være laget av tykkere metall for å forhindre at den bøyer seg eller føles spinkel. Denne økningen i tykkelse øker også materialkostnaden og vekten til pinnen.

Standard tykkelse etter størrelsestabell

Typisk pinnetykkelse basert på størrelse

| Pinnestørrelse (lengste dimensjon) | Standard tykkelse | Hvorfor det er nødvendig |

|---|---|---|

| 0.75" – 1.25" | 1,2 mm – 1,5 mm | Gir standard holdbarhet for vanlige, bærbare størrelser. |

| 1,5" – 2,0" | 1,5 mm – 2,0 mm | Økt tykkelse er avgjørende for å forhindre bøyning eller vridning. |

| 2,0"+ | 2,0 mm+ | Nødvendig for absolutt strukturell stabilitet på store, tunge deler. |

Et dypdykk i designkompleksitet

Det er her nyansene til prising virkelig kommer inn. En "kompleks" design koster mer fordi den krever mer dyktig arbeidskraft, mer tid og noen ganger spesialiserte materialer. La oss bryte ned hver faktor som bidrar til kompleksitet.

Kompleksitetsfaktor #1: Antall farger

Den gode nyheten er at de fleste pinneprodusenter inkluderer et sjenerøst antall emaljefarger gratis - vanligvis opptil syv. For de fleste design er dette mer enn nok. Men hvis kunstverket ditt er spesielt fargerikt, vil hver ekstra farge utover gratisgrensen legge til en liten avgift, vanligvis rundt $0,04 til $0,10 per pin.

Årsaken til denne ekstra kostnaden er arbeidskraft. Emaljefarger fylles for hånd, en om gangen, av våre dyktige håndverkere. En 10-farger pin krever nesten dobbelt så mye manuelt arbeid som en 5-farger pin, noe som øker produksjonstiden og potensialet for feil. Dette er et avgjørende punkt vi dekker i vår guide til Pantone fargematching.

Kompleksitetsfaktor #2: Utskjæringer (negativ plass)

Utskjæringer er alle hull eller hule områder som er stukket helt gjennom metallet på pinnen. De kan legge til mye visuell interesse og en følelse av letthet til et design.

Imidlertid øker de kostnadene fordi å lage utskjæringer krever en mer kompleks, todelt form og et ekstra produksjonstrinn (piercing). Denne ekstra prosessen øker også risikoen for at tappen vrir seg eller brekker under produksjonen, noe som fører til en noe høyere defektrate som må tas med i prisen.

Kompleksitetsfaktor nr. 3: En masterguide til prissetting av spesialeffekter

Legger til spesialeffekter er en fantastisk måte å øke pinnens "wow"-faktor, men disse premium-funksjonene kommer mot en ekstra kostnad på grunn av spesialiserte materialer og ekstra arbeid.

Kostnadstabellen for spesialeffekter

Hvorfor spesialeffekter øker prisen

| Spesiell effekt | Hvorfor det øker kostnadene | Typisk kostnadsøkning (per pin) |

|---|---|---|

| Glitter emalje | Selve glitteret er en dyrere råvare, og det må blandes forsiktig inn i emaljen. | +$0,25 – $0,55 |

| Glød i mørket | Det fosforescerende pulveret som brukes til glødeeffekten er et spesialisert, kostbart tilsetningsstoff. | +$0,25 – $0,50 |

| Gjennomsiktig emalje | Krever en to-trinns prosess: først teksturere metallet under, deretter påføre den spesielle emaljen. | +$0,20+ |

| Antikk plating | Krever en ekstra kjemisk prosess for å påføre den mørke patinaen, etterfulgt av håndpolering. | +$0,10+ |

Kompleksitetsfaktor #4: Kinetiske elementer (spinnere, glidere og danglere)

Pinner med bevegelige deler er blant de mest komplekse og dyre å produsere. Grunnen er enkel: du kjøper ikke en pinne; du kjøper to eller flere separate pinner som deretter må monteres for hånd. En spinnerpinne, for eksempel, krever en hovedpinne og en spinnerbit. Hver av disse delene trenger sin egen form og sitt eget produksjonsløp. Deretter må de settes forsiktig sammen med en nagle. Denne doblingen av produksjonen og tillegg av manuell montering er grunnen til at disse funksjonene krever en premium pris, og legger ofte til $0,50 til $1,50 eller mer til kostnaden per pin.

Kompleksitetsfaktor #5: 3D vs. 2D-former

Valget mellom en standard 2D-form og en skulpturell 3D-form er en av de største driverne for kompleksitet og kostnad. En 2D-pinne har flate, distinkte nivåer, mens en 3D-pinne har jevnt buede overflater på flere nivåer. Den høyere kostnaden for en 3D-pinne kommer fra tre områder: spesialisert 3D-designarbeid, en mye mer tidkrevende og kompleks støpeprosess og en mer involvert produksjonsmetode for støping. For en fullstendig utforskning av dette emnet, se vår dybdeveiledning: 3D-form vs. 2D-form for tilpassede pinner.

Fra enkelt til superladet: Tre virkelige scenarier

La oss se hvordan disse faktorene kombineres i praksis ved å se på tre vanlige typer pin-bestillinger.

Scenario 1: Den budsjettbevisste Giveaway-nålen

- Mål: Maksimal merkesynlighet for minimumskostnader på en messe.

- Valg: Liten størrelse (1,0 tommer), høy mengde (5000), enkel logodesign, 4 farger, standard myk emalje, og en standard sommerfuglclutch.

- Resulterende kostnadsprofil: Veldig lav. Den høye mengden og den enkle designen holder prisen per pin på et absolutt minimum.

Scenario 2: Mid-Range E-commerce Retail Pin

- Mål: Et vakkert, ønskelig produkt for en nettbutikk som kan selge for $10-$15.

- Valg: Standardstørrelse (1,25 tommer), middels mengde (300), intrikat kunstnerisk design, 7 farger, myk emalje med glitter i én farge, en gummiclutch og en tilpasset støttekort.

- Resulterende kostnadsprofil: Medium. Kompleksiteten i designet og tillegget av glitter og tilpasset emballasje øker kostnadene, men prisen er fortsatt godt egnet for fortjenestemarginer i detaljhandelen.

Scenario 3: Premium Corporate Award Pin

- Mål: En prestisjetung pris med høy verdi for en medarbeider med topp ytelse.

- Valg: Stor størrelse (1,75 tommer), lavt antall (50), 3D-støpt design, ingen emaljefarge, antikk gull plating, to deluxe låser pin rygger, og presentert i en fløyelsboks.

- Resulterende kostnadsprofil: Veldig høy. Den lave mengden, den store størrelsen og de mange premium-kompleksitetene (3D-form, deluxe clutcher, premium-emballasje) bidrar alle til en høy pris per pinne, noe som er passende for en pris av høy verdi.

Konklusjon: Du har kontroll over kostnadene til pinnene dine

Den endelige kostnaden for en egendefinert pin er ikke et mysterium; det er et direkte resultat av en rekke tilsiktede design- og produksjonsvalg. Ved å forstå hvordan størrelse og kompleksitet påvirker bruken av materialer, arbeidskraft og maskintid, går du fra å være en enkel pristaker til en strategisk prosjektleder.

Du har nå en insiders forståelse som lar deg kontrollere budsjettet ditt uten å kompromittere visjonen din. Du kan bestemme hvor du skal investere – i en større størrelse, en førsteklasses finish eller en unik spesialeffekt – og hvor du skal spare, for å sikre at sluttproduktet ditt er en perfekt gjenspeiling av både kreativiteten din og dine strategiske mål. Det siste trinnet er å finne en partner som kan bringe det hele til live, en prosess vi dekker i vår guide om hvordan velge en pålitelig produsent.

La våre eksperter hjelpe deg med å balansere design og budsjett

Å navigere i forholdet mellom et komplekst design og et fast budsjett kan være utfordrende. Vårt team av pin-eksperter spesialiserer seg på å finne kreative løsninger for å bringe din visjon til live, kostnadseffektivt. Send oss ditt design, så gir vi et gratis, altomfattende tilbud og gir ekspertanbefalinger om hvordan du oppnår best mulig pin for budsjettet ditt.