すべてのカスタムピンは、マスターモールドとなるよう細心の注意を払って彫刻されたスチールのブロックとして誕生します。しかし、金型の彫り方がピン全体の特徴を決定づけます。それは、クリーンでグラフィックなラインを備えたクラシックなエンブレムでしょうか、それとも流れるような立体的な輪郭を備えた本物のような彫刻でしょうか?これは 2D 金型と 3D 金型の基本的な選択であり、ピンの外観、感触、コストに影響を与える決定です。

これは、この重要な製造上の決定を理解するための決定的なガイドです。工場現場の奥深くまで案内し、2D と 3D 金型の背後にある技術、芸術性、戦略を探ります。この包括的なガイドを読み終えるまでに、どのプロセスがあなたのデザイン、ブランド、予算に最適であるかを判断できるようになり、最終製品が思い描いた通りのインパクトを確実に生み出すことができるようになります。これは作成プロセスの重要なステップであり、これについては次の記事で説明します。 カスタムラペルピンの究極ガイド。

目次

中心的な概念: 2D ピンと 3D ピンの違いは何ですか?

技術的な詳細に入る前に、シンプルで直接的な答えから始めましょう。あ 2Dピン は平坦で明確なレベルを備えたデザインで、通常、一方が盛り上がっていてもう一方が凹んでいて、古典的な漫画のようなすっきりとしたグラフィックな外観を作り出しています。あ 3Dピン一方、 は滑らかに湾曲し、丸く、輪郭のある表面を備えたデザインで、コインの表面のようなリアルで彫刻的な複数レベルの効果を生み出します。

コアコンセプト比較表

主な違いの概要: 2D ピンと 3D ピン

| 特徴 | 2Dモールドピン | 3Dモールドピン |

|---|---|---|

| 表面 | 平坦なレベル、鋭角、はっきりとした凹凸のある領域。 | 滑らかに湾曲し、丸みを帯びた、輪郭のある表面。 |

| 外観 | グラフィック、クリーン、大胆、クラシックな「エナメルピン」の外観。 | 彫刻的、現実的、本物そっくり、次元的。 |

| 最適な用途 | ロゴ、テキスト、シンプルなイラスト、最も標準的なデザイン。 | 顔、キャラクター、建物、乗り物、複雑なテクスチャ。 |

| 製造業 | 型打ち工程を簡素化。 | 複雑なダイカスト工程。 |

| 料金 | 標準料金(より手頃な価格)。 | プレミアムコスト (大幅に高価)。 |

工場の現場: 各金型がどのように作られ、使用されるのかを詳しく知る

最終製品を真に評価するには、2D ピンと 3D ピンの背後にある異なる製造工程を理解することが役立ちます。このプロセス自体が、ピンの最終的な外観、感触、さらには使用される素材を決定します。

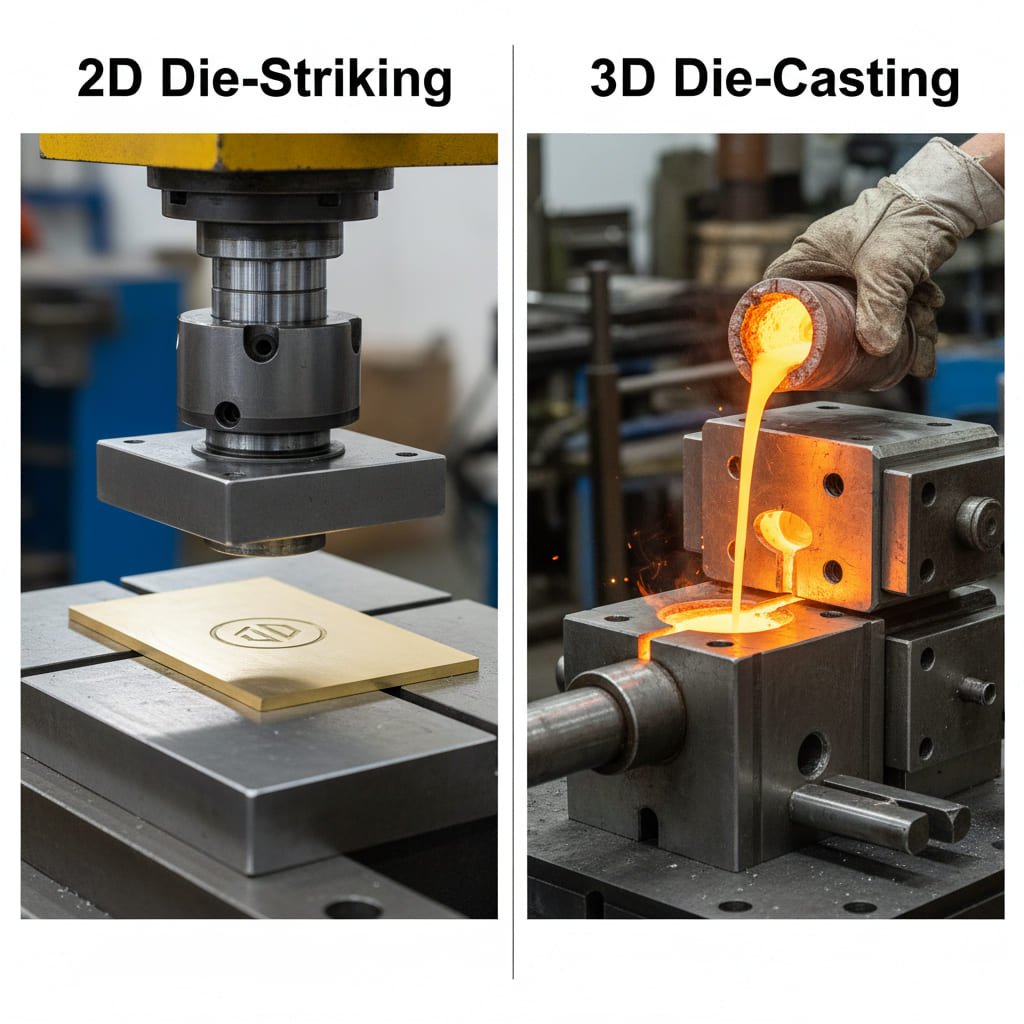

2D モールド プロセス: ストライクの芸術

2D プロセスは、ほとんどのカスタム ピンの基礎です。これは、きれいなグラフィック デザインを作成するための効率的かつ正確な方法です。

- 型の作成: CNC (コンピューター数値制御) マシンが 2D を彫刻するところから始まります。 ベクターファイル 硬化鋼のブロックにします。機械はアートワークのきれいなラインに従って、明確で平らなレベルの金型を作成します。

- 製造プロセス: 型打ち。 次に、強力な油圧プレスがこの金型を取り出し、強大な力で固体金属 (通常は真鍮、鉄、または銅) のシートに打ち付けます。この打撃により金属にデザインが刻印され、明確な凹凸が形成されます。このプロセスは、クラシック、ノーカラーの両方の基礎となります。 ダイス打ちピン そして伝統的な エナメルピン。

3D モールドプロセス: キャストの科学

3D ピンの作成はより複雑で彫刻的な芸術形式であり、さまざまなテクニックと材料が必要です。

- 型の作成: このプロセスはフラット ファイルではなく、3D デジタル モデルから始まります。次に、専用の多軸 CNC マシンが何時間もかけて、このモデルの流れるような輪郭のある表面をスチール製の型に注意深く彫り込みます。

- 製造プロセス: ダイカスト。 このプロセスでは、固体の金属シートをスタンピングする代わりに、溶融金属を射出することが含まれます。 亜鉛合金—高圧下で複雑な 3D 金型に押し込みます。

- なぜ亜鉛合金なのか? 亜鉛合金は、融点が低く、流動性に優れているため、3D ピンに最適な金属です。これにより、複雑な 3D モールドのあらゆる小さな隙間、曲線、微妙な輪郭を埋めることができ、彫刻の細部を完璧に捉えることができます。

製造工程比較表

技術的な違い: 2D 製造と 3D 製造

| 特徴 | 2Dモールドプロセス | 3Dモールドプロセス |

|---|---|---|

| アートワークの開始 | 2D ベクター ファイル (.AI、.EPS) | 3D デジタル モデル (.STL、.OBJ) |

| 金型の作成 | 平らなレベルの CNC 彫刻がより簡単かつ高速になりました。 | 複雑で多軸の、時間のかかる彫刻彫刻。 |

| 製造方法 | ダイストライキング (無垢金属のプレス加工) | ダイカスト (溶融金属の注入) |

| 一次ベースメタル | 真鍮、鉄、銅 | 亜鉛合金 |

デザイナーズ ガイド: 2D デザインと 3D デザインのアプローチ方法

選択した製造プロセスを最大限に活用するには、そのプロセス特有の強みを念頭に置いて設計することが役立ちます。平面的なグラフィックレイヤーで考えているのか、それとも彫刻的で流れるような深さで考えているのか?

2D デザインをマスターする: 奥行きの錯覚を作成する

2D の「平面」の世界であっても、強力な立体感を生み出すことができます。これは「2.5D」効果と呼ばれることもあります。複数の異なるレベル (凹んだ背景、中間レベルの要素、最上位の要素など) を使用することで、標準 2D ピンに奥行きと視覚的な面白さを加えることができます。これを別のものと組み合わせると、 金属メッキオプション この効果をさらに高めることができます。

3D デザインをマスターする: 彫刻家のように考える

真の 3D ピンを設計するには、光、影、形状について考える必要があります。ここでのキーコンセプトは、彫刻の古典的な用語である「レリーフ」です。

- ローリリーフ: これには、コインの顔の横顔のような、微妙で浅い彫刻が含まれます。細部は存在しますが、劇的に向上するわけではありません。

- ハイレリーフ: これには、大幅な深さと陰影を備えた深くてドラマチックな彫刻が含まれ、より際立った本物のような効果が作成されます。

3D デザインを作成するには、専門の 3D デジタル アーティストがモデルを構築する必要があります。これは 2D ロゴから簡単に変換できるものではありません。当社の社内設計チームには 3D モデリングの専門家がおり、お客様と協力してコンセプトを完全に彫刻されたデジタル モデルに変換し、金型作成の準備が整います。

戦略的な選択: 3D 金型をいつ使用するか

3D 金型はプレミアム オプションであり、リアリズムと「驚き」の要素が最優先されるいくつかの特定のシナリオでは優れた選択肢です。

3D 金型が正しい選択となるのはどのような場合ですか?

| 使用事例 | 3D がより適している理由 |

|---|---|

| 顔、人物、キャラクター | 2D ピンでは、フラットな漫画のような表現しか作成できません。 3D モールドは顔の微妙な曲線やキャラクターの輪郭を捉え、生命を吹き込みます。 |

| 建物と建築 | 3D 金型は、建物の遠近感、奥行き、複雑な詳細を正確に表現し、見事なミニチュア レプリカを作成できます。 |

| 車両、機械、製品 | 車の滑らかな曲線、エンジンの複雑な機械、製品の特定の形状を捉えるには、リアルな外観を実現するために 3D 金型が不可欠です。 |

| 詳細な自然テクスチャ | 動物の毛皮、樹皮、岩の表面などの有機的なテクスチャを再現する必要があるデザインの場合、3D 金型を使用すると、より現実的で触感のある仕上がりが得られます。 |

| ピナクル賞 & プレミアムギフト | 一流の賞やハイエンドの企業ギフトの場合、3D ピンの彫刻品質は、比類のない「驚き」の要素と、大幅に高い知覚価値をもたらします。 |

財務上の現実: 3D 金型のコストが高くなる理由

3D ピンに必要な投資について透明性を保つことが重要です。価格の高騰は、プロセスのあらゆる段階での複雑さの増加の直接の結果です。

- 専門的なデザイン作業: 3D デジタル モデルを最初から作成するには、専門のアーティストが必要となり、設計時間が大幅に長くなります。

- 複雑な金型の作成: 3D 金型の CNC 加工プロセスは、標準の 2D 金型よりもはるかに複雑で、加工時間が何時間もかかります。

- ダイカストプロセス: 溶融金属を射出するプロセスはより複雑で、単純なスタンピングとは異なる設備が必要です。

これらの要因により、3D 成形ピンのピンあたりのコストが高くなることが予想されます。 1 回限りの金型費用も、標準の 2D ピンよりも大幅に高くなります。完全な概要については、弊社を参照してください。 ピン価格設定の完全ガイド。

結論: 明快さと個性のどちらかを選択する

2D モールドと 3D モールドのどちらを選択するかは、クラシックでグラフィックの鮮明さと、現実的で彫刻的なキャラクターの戦略的な選択となります。 2D モールドは、大部分のデザイン、特にロゴやテキストに最適で多用途な主力製品です。 3D モールドは、本物のような奥行きを表現し、本当に忘れられないインパクトのある作品を作成する必要がある場合に使用する専門家のツールです。

各オプションの背後にある独自の強みとプロセスを理解することで、デザイン、ブランドのメッセージ、予算と完全に一致する、自信を持って情報に基づいた決定を下すことができるようになります。この選択により、以下のものを作成できます。 クリエイティブなマーケティングツール 名誉ある賞に。

2D ピンと 3D ピンに関するよくある質問

- 私の 2D ロゴを 3D ピンにすることはできますか?

- はい、絶対に!当社の 3D アーティストは、フラットな 2D ロゴを巧みに解釈して 3D モデルに変換し、深さ、面取り、テクスチャを追加して、彫刻のような形で生命を吹き込みます。

- 3D ピンにエナメル色を追加できますか?

- 可能ですが、プロセスが非常に複雑で、多くの場合費用がかかります。ほとんどの 3D ピンは、複雑な彫刻の細部を最大限に見せるために、すべて金属製のデザインとして残されており、多くの場合はアンティーク仕上げが施されています。色を追加すると、デザインの細かい輪郭が見えにくくなる場合があります。

- 3D ピンは常に 2D ピンよりも「優れている」のでしょうか?

- 全くない。これらは単に、さまざまな仕事に適したさまざまなツールです。すっきりとした大胆な企業ロゴの場合、多くの場合、2D ピンの方が読みやすくグラフィックが正確であるため、優れています。 3D が「優れている」のは、目標がリアリズムと彫刻の深さである場合に限られます。

- 3D ピンの価格は、スピナーなどの可動部品を備えたピンと同じですか?

- 多くの場合、コストは同様のプレミアム範囲にありますが、理由は異なります。 3D ピンのコストは複雑な金型から発生します。スピナーのコストは、2 つの別々のピン部品の製造と組み立てから発生します。どちらも高級品とみなされます 特撮。

デザインに 2D が必要か、3D が必要かわからないですか?当社の専門家がアドバイスいたします。

複雑な 2D デザインと真の 3D ピンの間の境界線は微妙な場合があります。私たちの経験豊富なデザイナーのチームがあなたのアートワークをレビューし、どのプロセスがあなたのビジョンを最も効果的に、そして予算内で実現するかについて専門家の推奨事項を提供します。